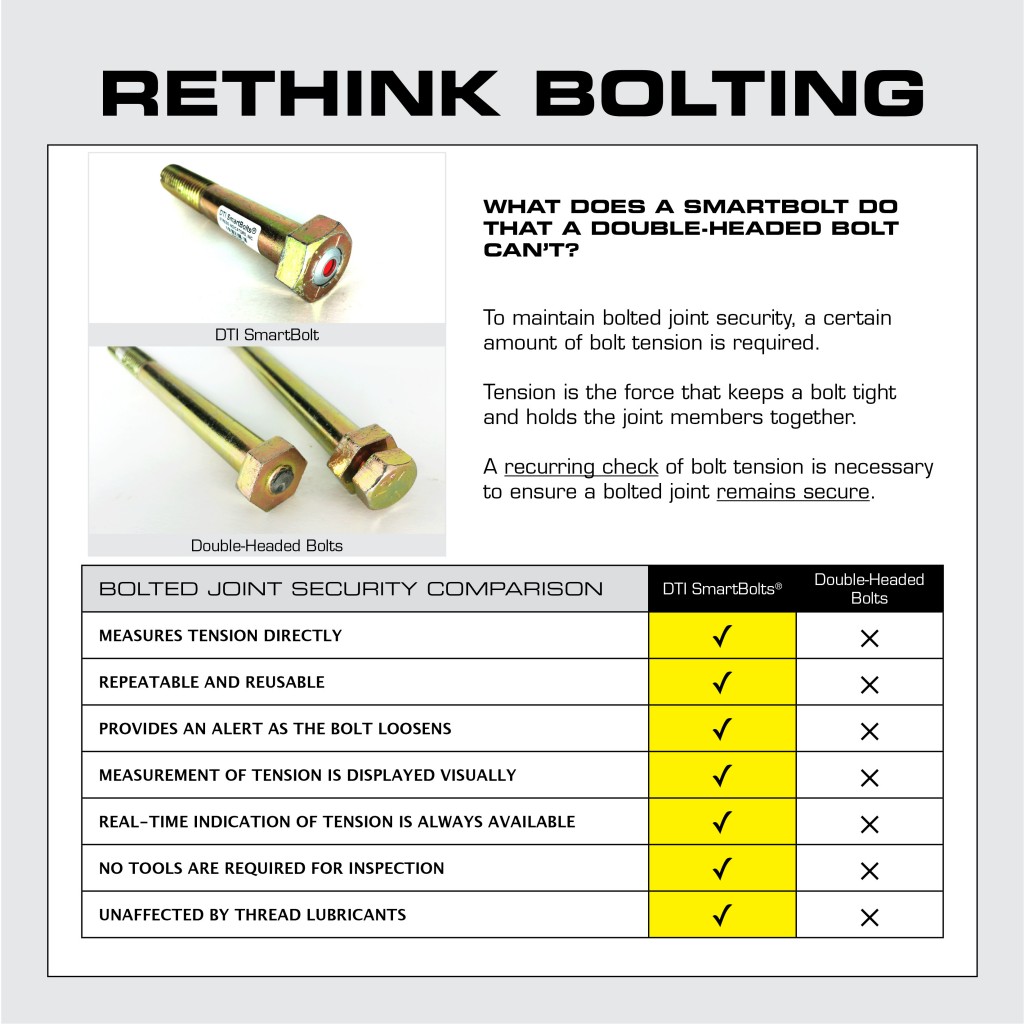

Double-headed bolts function by “twisting off” an auxiliary hex head once a designated torque has been reached. It is a method that indirectly attempts to indicate bolt tension. However, due to its reliance on torque, this system has several disadvantages when compared with the SmartBolts® Visual Indication System™.

Are you using double-headed bolts in an attempt to achieve proper bolt tension?

If so, it means that the bolts you are tightening are essential components and need to be tightened with a certain measurable amount of accuracy. Using double-headed bolts also means that you will be unlikely to reliably achieve or maintain the proper bolt tension to make these bolted joints secure.

Let’s take the example of a bolted joint connection within electrical busway. Busway is a modular system of electrical distribution. The system depends on secure bolted joint connections at the critical bridge joints where multiple busbars meet. To prevent electrical disruptions, these bolts must be tightened to a certain tension.

How can you be sure that these important bolts have been properly tightened, and remain that way for years to come?

First and foremost, a certain amount of bolt tension must be developed to ensure a bolted joint is secure.

Double-headed bolts create a false sense of security because they imply that torque equals tension and that a joint is secure because its auxiliary hex head is twisted off with torque. Attempting to achieve bolt tension by measuring torque results in well-documented, but unpredictable, variations in applied tension. Additionally, manufacturing variations, as well as deterioration of thread conditions, can lead to improper tension developed once the auxiliary hex head breaks off.

Bolt tension must also be checked periodically to ensure a bolted joint remains secure.

Maintenance for double-headed bolts is time-consuming because a calibrated torque wrench must be applied to every bolt. Furthermore, once the auxiliary hex head has been twisted off, workers are exposed to the remaining jagged metal stub.

Now, you can use SmartBolts to measure tension directly, at any time, with a visual indicator.

Unlike double-headed bolts, SmartBolts ensure efficient installation and maintenance procedures, and can be reused indefinitely. The SmartBolts® Visual Indication System™ provides an accurate visual representation of actual bolt tension, in real time. When your bolts are important, you need more than an estimate – you need SmartBolts.