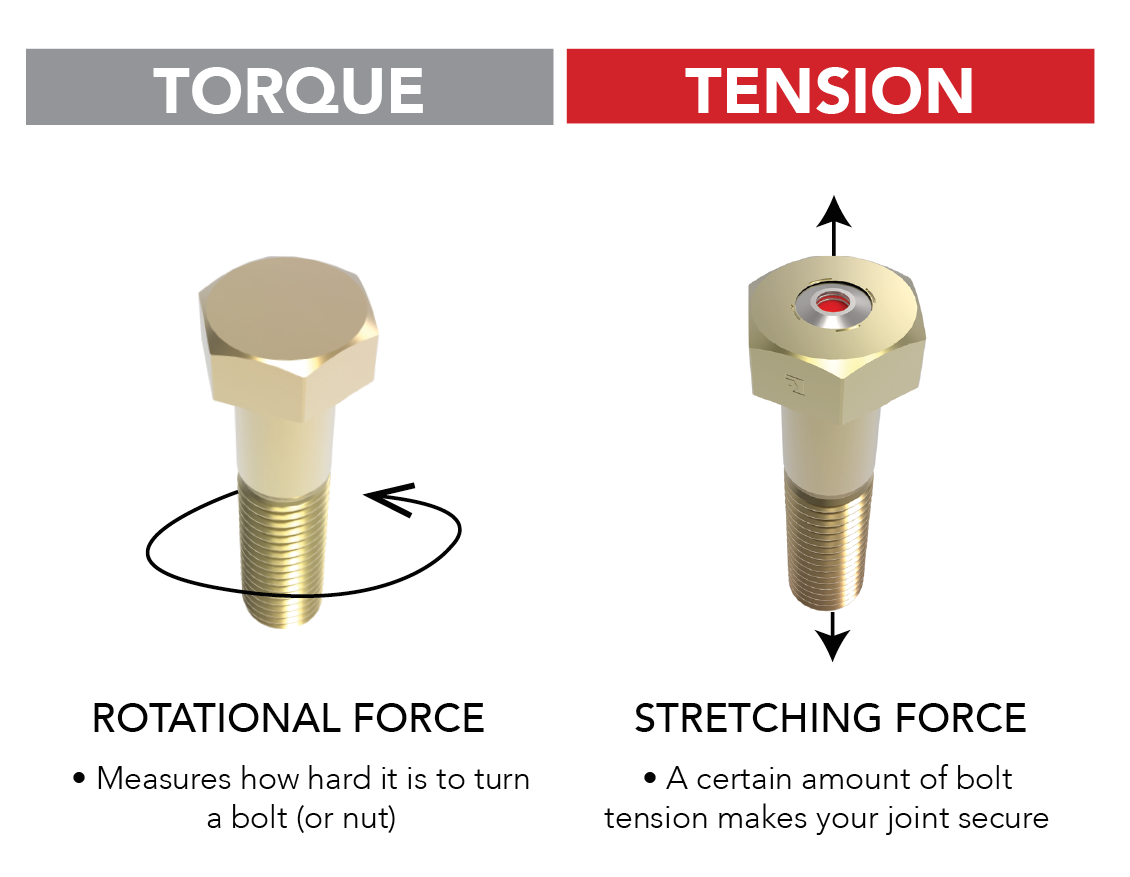

The traditional method for tightening fasteners is to turn the bolt head or nut using a torque wrench. While the tool may be very accurate, measuring torque only measures how difficult it is to turn the bolt.

Measuring rotational force provides little information about what is actually holding your critical joints together – these are clamp force or bolt tension – NOT torque!

Why Torque Readings are Unreliable

It is virtually impossible to know how much torque force is just to overcome friction factors! And there are 70 friction factors that can impact torque readings!

It is virtually impossible to know how much torque force is just to overcome friction factors! And there are 70 friction factors that can impact torque readings!

These factors include the amount of rust, type of plating, whether the nut or head is turned, the lubrication used, the type of washer and over 60 others.

This makes the torque-tension relationship very unpredictable and can lead to costly breakdowns and downtime — even serious accidents.

‘Bolt Stretch’ is the ONLY 100% Accurate Way of Knowing Your Critical Bolted Joints are Secure

Direct tension indicators respond to fastener tension ONLY, ignoring torque inputs — providing a true measure of joint tightness.

Tension or stretching force, is the only factor that ensures your joint is “tight”.

SmartBolts® Provide VISUAL INDICATION of TENSION!

The SmartBolts® Visual Indication System™ built-in tension indicator turns from red to black when proper tension has been reached — and is completely reversible for the life of the fastener.

SmartBolts ensure proper preload at installation and continuously monitor bolt tension for as long as your bolted joint is in service — giving you peace of mind that your critical bolted joints are tight.

SmartBolts are on the job worldwide keeping production up and running, saving inspection time and maintenance, and helping to prevent accidents.

Industries such as Manufacturing, Mining, Renewable Energy, Industrial Automation, Heavy Equipment, Electrical Distribution, Transportation, Cranes/Shiploaders, Structural, Bulk Materials Handling, and Oil & Gas use SmartBolts in their critical bolted applications.

SmartBolts have the same form and function as the bolts you’re using now. Replacing them is simply a matter of removing the ordinary bolt and installing the matching SmartBolt. Tighten until the indicator turns black and you’re ready to go!

To learn more about SmartBolts please contact one of our knowledgeable SmartBolts consultants. They will be happy to evaluate your application and calculate the potential cost savings you’ll realize when you put SmartBolts to work monitoring your critical bolted joints.