WHAT ARE CONTROLLED BOLTED CONNECTIONS?

Bolted connections play a critical role in ensuring the integrity and safety of structures and equipment. Controlled bolted connections refers to fastening systems where bolt tension is precisely managed to prevent loosening, failure, and costly downtime. Traditional methods rely on torque measurement, which can lead to unreliable results.

HOW SMARTBOLTS ENSURE CONTROLLED BOLTED CONNECTIONS

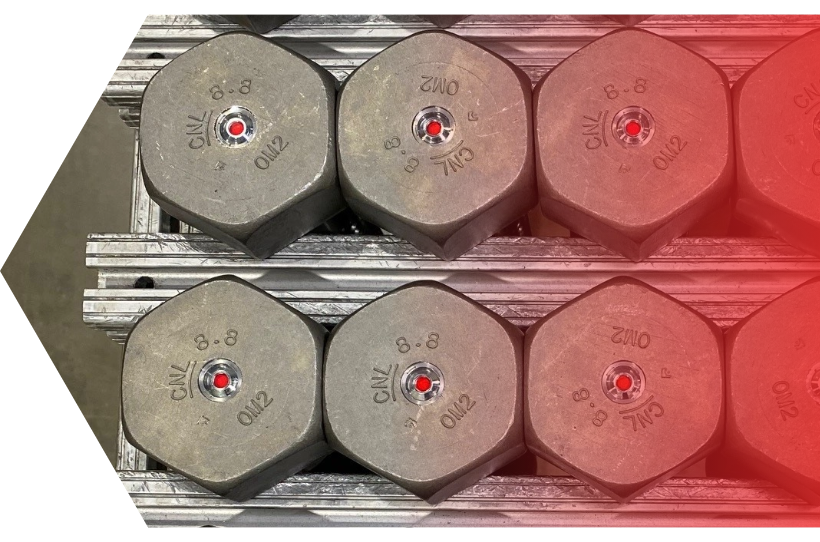

SmartBolts® take the guesswork out of bolted connections with their Visual Indication System™, which provides real-time tension monitoring. Unlike traditional torque-based methods, SmartBolts visually indicate whether a bolt is properly tightened, ensuring consistent, reliable, and controlled connections every time.

WHY SMARTBOLTS?

INDUSTRIES & APPLICATIONS

Controlled bolted connections are essential in high-stakes environments where failure is not an option. SmartBolts are trusted in industries such as:

MINING & HEAVY EQUIPMENT

Secure vital components on excavators, haul trucks, and loaders.

CONSTRUCTION & INFRASTRUCTURE

Ensure the safety and longevity of bolted structures.

OIL & GAS

Prevent leaks and structural failures in high-pressure environments.

RENEWABLE ENERGY

Maintain reliability in wind turbines and solar panel mounts.

TRADITIONAL BOLTS VS. SMARTBOLTS

| Feature | Traditional Bolts | SmartBolts |

|---|---|---|

| Tension Accuracy | Inconsistent | Real-time Visual Indication |

| Maintenance Needs | Regular Inspections Required | Instant Visual Check |

| Safety & Reliability | Potential for Loosening | Controlled, Reliable Connection |