Are you using a torque wrench to tighten your bolts? If so, it means that the bolts you are tightening are essential components and need to be tightened with a certain measurable amount of accuracy.

For example, consider the bolt that secures the lawnmower blade to an engine. The designer of the assembly has provided a torque specification for this bolt so that the lawnmower blade will not come loose while in service. Keeping the blade securely tightened is necessary to be able to properly use the lawn mower and to avoid serious safety risk. The fact that this bolt has a torque specification means it is an important bolt to secure an important bolted joint. How can you be sure that this important bolt has been properly tightened?

Torque specifications are supplied so that a bolt will be tightened to a certain amount of tension. In our lawnmower, bolt tension is what keeps the lawnmower blade securely connected to the engine. If tension is too low, the lawnmower blade will be loose. If tension is too high, the bolted joint can be damaged and lose its structural integrity.

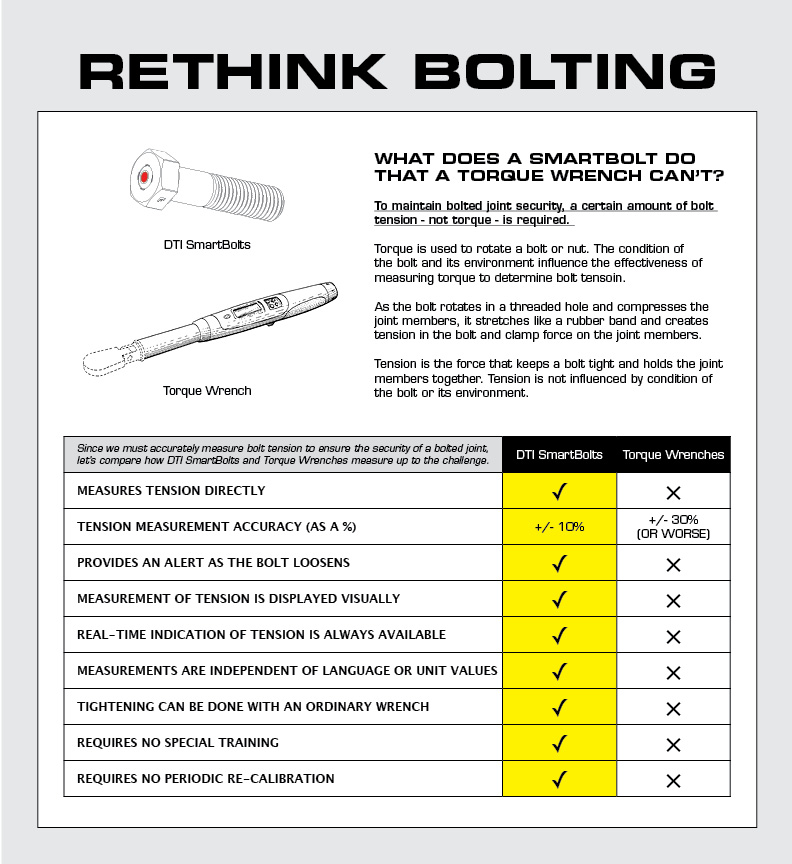

Tension traditionally has been difficult to measure directly, so torque measurement has been used as a method to estimate tension. Torque is a measure of how difficult it is to rotate a bolt or nut. The premise is, by measuring how difficult it is to turn a bolt or nut, the bolt tension can be predictably estimated. Unfortunately, this often isn’t true. Torque and tension are different forces, with a weak relationship that is always changing. To measure tension, it is best to measure it directly.

Now you can use SmartBolts to measure tension directly with a visual indicator. Unlike torque wrenches, SmartBolts can be operated without special tools or training, and don’t need periodic re-calibrataion. The SmartBolts® Visual Indication System™ provides an accurate visual representation of actual bolt tension, in real time. When your bolts are important, you need more than an estimate – you need SmartBolts.