Most bolts are lazy.

A machined piece of steel can’t do much on its own. A bolt doesn’t tighten itself, and it won’t tell you if it becomes loose. What else is your bolt not telling you?

Bolts have complex and shifting relationships with their surroundings. Every day, in thousands of applications, clamp forces reach dangerous levels because of unobserved changes within a bolted joint. These unobserved changes can increase the risk of bolted joint failure.

Most bolts don’t tell you when they’re tight.

Let’s assume you are using one of the most common tools to install a bolt, a calibrated torque wrench. Something you might not know, however, is that a torque wrench doesn’t tell you if your bolt is tight. It tells you how hard it is to turn the bolt (or nut).

Torque is the force required to turn something. A bolt is “tight” when it creates a desired clamp force. Bolts are installed by torquing the bolt (or nut) with a wrench, but often the end result is not the desired clamp force.

So bolts need torque to be tightened, but may not be tight if torqued?

Exactly. There are simply too many factors associated with torque to make it an accurate measure of whether a bolt is tight or not. The factors that can complicate torque are so numerous the we group them all into a single term – the nut factor.

The nut factor is not precise – it’s an estimate that is different for every bolt and changes every time a bolt is tightened. Any time torque is measured, the nut factor plays a significant role in complicating the result, often leading to the development of improper clamp force.

“In this world nothing can be said to be certain, except death, taxes, and bolts loosening.”

Most bolts don’t tell you when they’re loose.

Loose bolts are a problem for everybody. Many products help mitigate the problem (wedge-locking washers, thread-locking fluid, etc.) but none solve it entirely. Without a consistent inspection and maintenance plan, all bolts are likely to become loose.

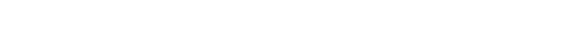

It can be difficult to know when a bolt is loose. Often, a loose bolt looks exactly the same as a tight bolt. When does a bolt become loose?

Short-Term Preload Loss

Bolts loosen immediately once installed. Engineers refer to this short-term loss of clamp force as relaxation. In some instances, a relaxation of 10% to 20% is common. When tightening a bolt, the surfaces under load are deformed and flattened in a process known as embedment. A degree of embedment is inevitable and can lead directly to the loosening of a bolt.

Long-Term Preload Loss

Bolts continue to loosen over extended periods for a variety of reasons. A common cause of long-term preload loss is vibration. Even the slightest vibrations can introduce enough instability and relative motion to cause loosening. Many bolted joints also experience dynamic loads while in service, which further contribute to loss of preload.

Clearly, the most logical way to prevent bolted joint failures is to know whenever a bolt is loose.

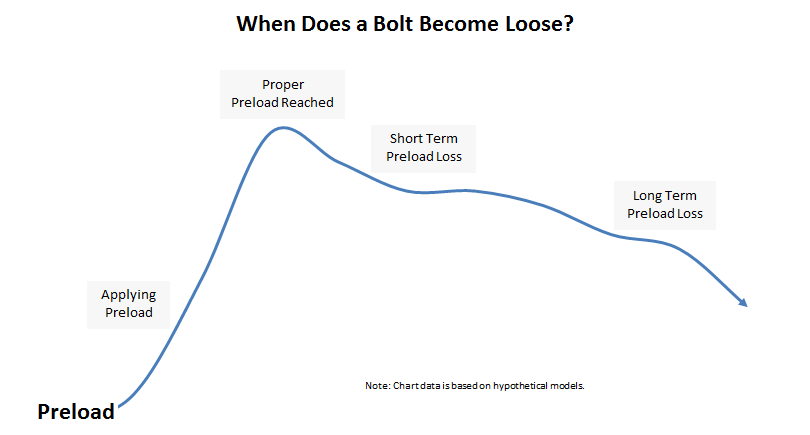

SmartBolts tell you when they’re tight and when they’re loose.

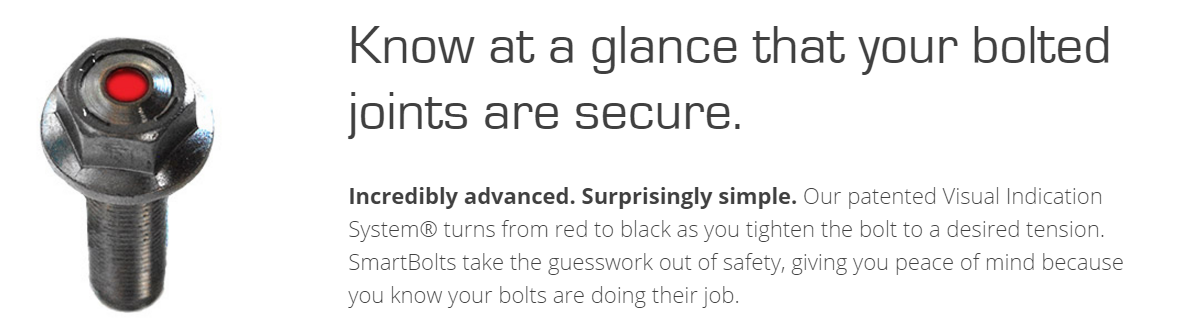

Now, you can know at a glance that your bolts are secure. SmartBolts use our proprietary Visual Indication System™ to provide a color-coded real-time measurement of clamp force.

SmartBolts were developed to make new and existing bolting installations safer and more efficient. Plus, no special training or tools are required to rapidly install, inspect and maintain SmartBolts.

- Safer Operations

- Reduced Inspection and Maintenance Costs

- More Reliable, More Secure Bolted Joints

Are SmartBolts the right solution for your bolting problem?

Want to learn more about how SmartBolts could help you? Provide a description of your bolting application, issues, or goals to get started!