A PREVENTABLE FAILURE THAT COULD COST YOU MILLIONS

In 2002, a high-speed train derailed at Potters Bar in the UK after bolts on a stretcher bar failed. Seven lives were lost, and dozens more were injured. The cause? Loose bolts missed during inspections.

Rail networks operate under intense pressure: heavy traffic, high speeds, and harsh environmental conditions. Every mile of track contains thousands of bolts subjected to constant vibration and mechanical stress. Without reliable, real-time monitoring, even the best maintenance teams can miss a critical issue.

RAIL OPERATIONS

Preventive Maintenance

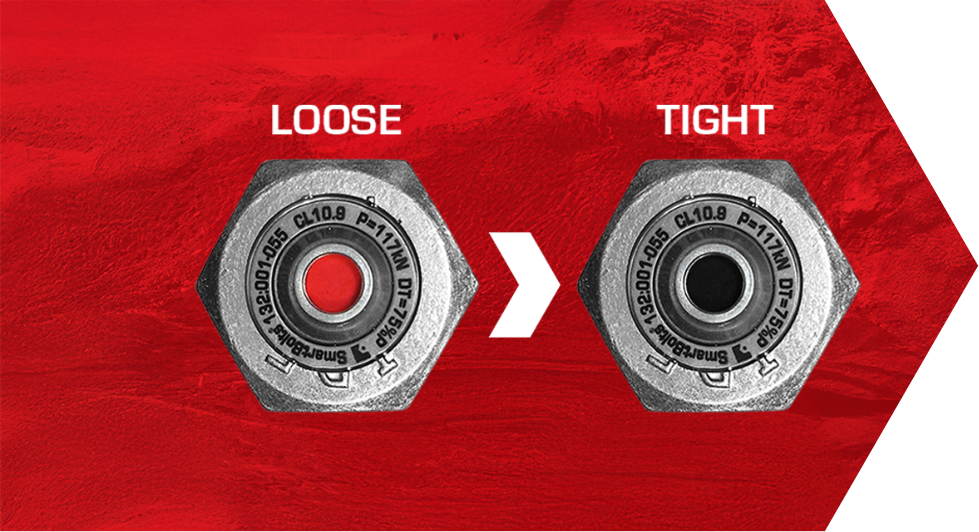

SmartBolts provide a simple yet powerful solution to help prevent costly and tragic rail incidents before they happen. Our patented Visual Indication System™ lets you:

- Instantly identify loose bolts during inspections.

- Save time and resources by re-tensioning only the bolts that need it.

- Spot potential failures before they happen, keeping operations running smoothly.

With SmartBolts, our technology goes beyond traditional methods. As you tighten a bolt, the Visual Indication System™ changes color, shifting from red to black. The color shift is proportional to bolt stretch, providing precise and trustworthy measurements every time.

KEEP YOUR RAIL OPERATIONS ON TRACK WITH SMARTBOLTS See It in Action!

See It in Action!

Rail systems operate under constant pressure and even one loose bolt can put passengers and rail workers at serious risk. SmartBolts make maintenance faster, safer, and more reliable. Watch the video to see how our color-changing Visual Indication System™ helps you monitor bolt tension in real time, prevent costly derailments, and protect both your operations and the people who rely on them.

PROTECT YOUR PEOPLE & OPERATIONS

Prevent failures before they happen. With SmartBolts, you’re not just improving the reliability of your rail infrastructure—you’re safeguarding passengers and workers, avoiding costly disruptions, and ensuring your operations run safely and smoothly.