Mining involves the extraction, processing, and handling of raw materials from the earth. It requires heavy-duty machinery and equipment that can be operated reliably in rugged environments. When extreme loads and constant vibrations push bolted joints to the limit, SmartBolts ensure mining operations remain productive.

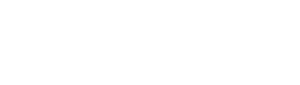

MOBILE STACKING CONVEYOR

TRUSS FRAME JOINT

In the open-pit mines of Chile, mobile stacking conveyors transport large volumes of raw materials onto a stockpile for future reclamation. A single conveyor is supported on a series of truss frames, each connected by a specially developed joint that allows the conveyor to follow uneven ground conditions and relieve stresses that could damage the structure.

HYDRAULIC MINING EXCAVATOR

SLEWING BEARING JOINT

Hydraulic mining excavators must support massive digging forces – the largest have bucket payloads that exceed 100 tons. Each payload, plus the majority of the weight of the excavator, is supported by critical slewing bearings that allow the machine to rotate independently of its undercarriage.

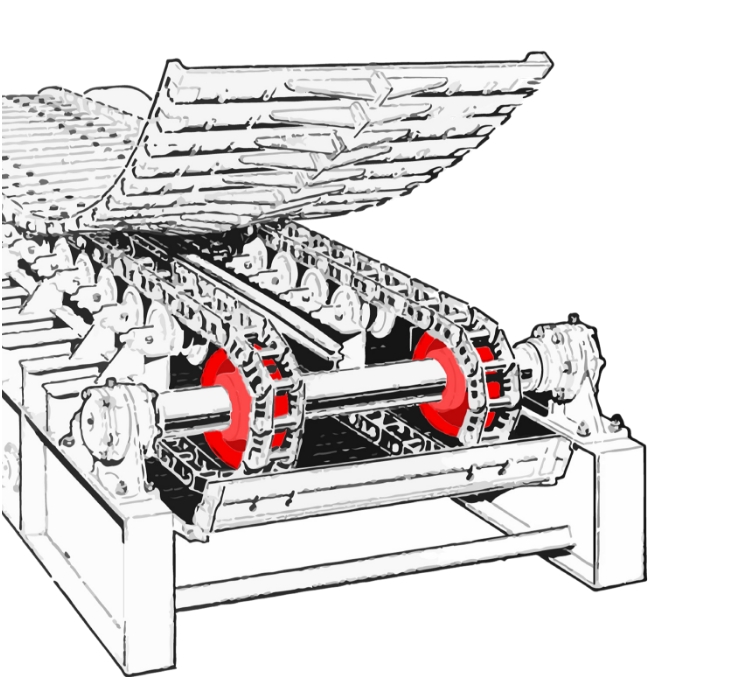

APRON FEEDER

DRIVE SHAFT SPROCKET JOINT

Apron feeders are rugged and heavy duty conveyors ideal for mineral processing applications. Raw material is dumped directly onto the apron feeder from mining trucks and transported to a crusher. The drive shaft sprocket is a bolted-on component that connects a rotating drive shaft with the chain and apron that transports the raw material.